▲Pre-sale support

Our company have a number of electric engineers, metal plate engineers, production process engineers who altogether forms our technical strength to provide professional Pre-sale services to the customers, such as technical negotiation, field investigation, simulated drawing and quick quotation.

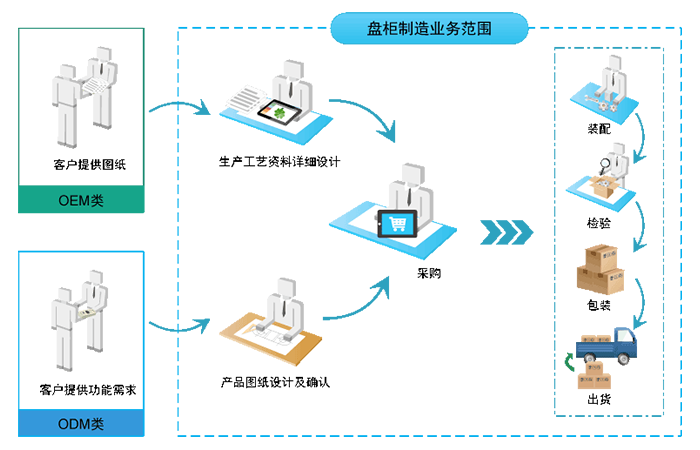

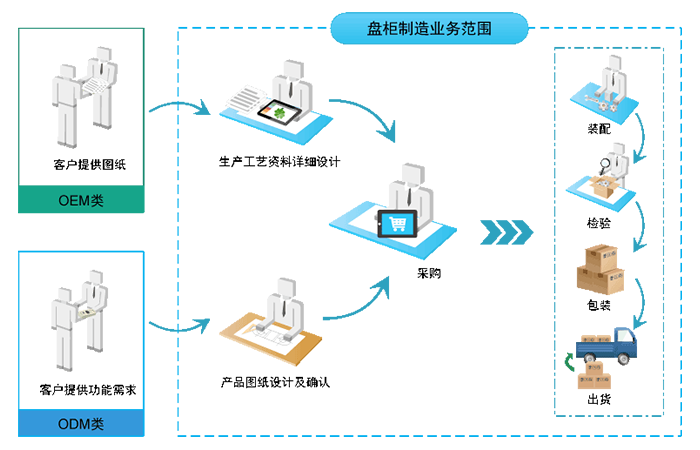

▲Technical flow

Our company provides OEM and ODM services for different technical conditions of different customers.

Our company have cultivated its raw material supply chain of electrical panels for many years and kept close relationship with multiple famous brands. Our company not only have built a steady domestic supplier system, it also has the capability to purchase overseas via international trade, so as to ensure the raw material supply of electrical panels in a timely and steady manner while controlling a competitive cost.

▲Deep collaboration with major electrical components brands

●Siemens system integrator

●ABB panel licensee

●Mitsubishi CC-LINK association

▲Perfect provision system of enclosures and cabinets

Besides the long term collaboration with famous cabinets manufacturers including Rittal, Vantage Control inc etc, our company have also developed several plate supplier nearby that produces non-standard cabinets and Cabinets to meet different requirement from our customers.

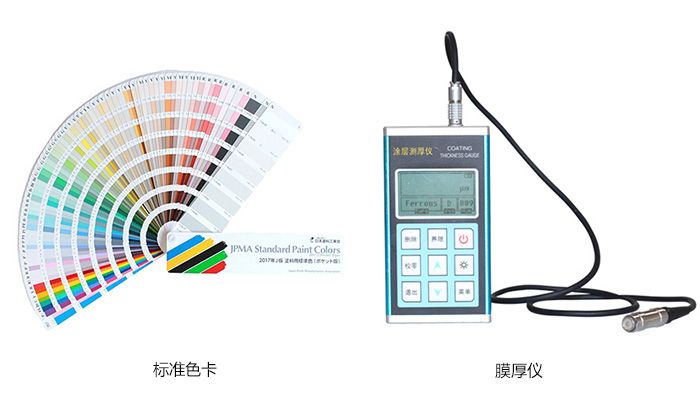

One of the long term plate suppliers is located in the same yard with us, which has multiple Japanese AMADA numerical control machining equipments and complete powder coating processes along with exquisite workmanship that could produce high quality cabinets and Cabinets in large batches for export.

Supplier sheet metal shop

Coating shop

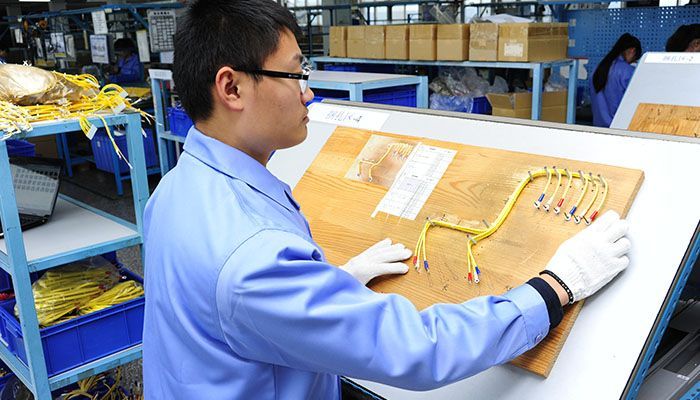

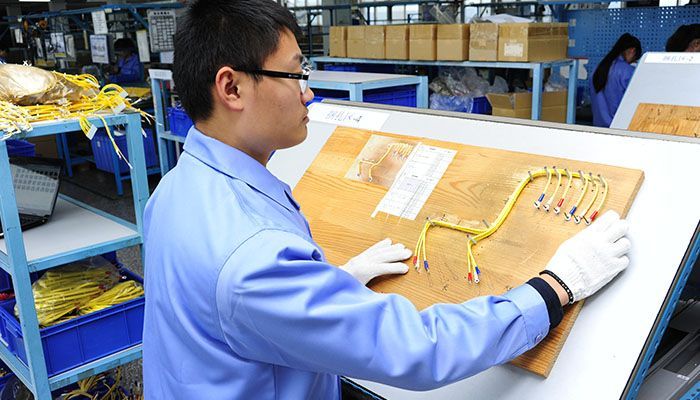

The assembly workshop set up prefabrication group (rail line slot processing, tag printing, wire harness) based on the production and assembly traits of electrical panels, which is able to plan related auxiliary operations via tools like CAD and data visualization to prefabricate necessary items and ultimately shorten the delivery time. In the final panel assembly phase, we set up two assembly lines and several discrete assembly groups for standard products and non-standard products respectively, based on the standardization degree and size of batches of certain customer.

▲Equipped with dedicated equipments and tools to continuously increase assembly quality and job efficiency

▲Able to meet panel technology requirement of different styles for Japanese, European and domestic customers

▲Unique equipments and tools as well as process design that are aimed to increase added value in terms of appearance consistency and maintainability

Standard wiring

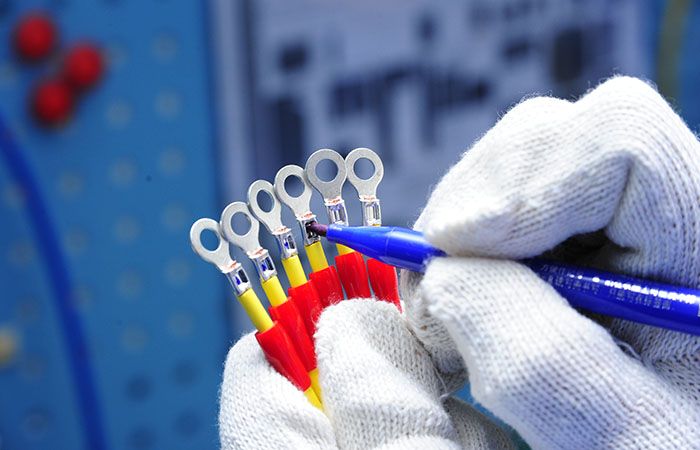

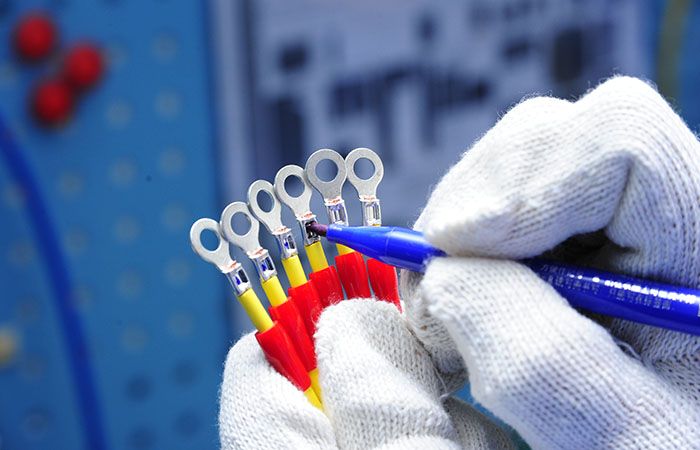

Crimping tools

Automatic cutting machine

Terminal marking printer

Busbar processing machine

Our company strictly follows ISO9001 management system to govern the end to end processes of our panel manufacturing business, and set various roles of inspectors and quality engineers to ensure continuous improvement on top of client satisfaction to our products and services, and keep building good products for our customers and users.

▲Accepting inspection:

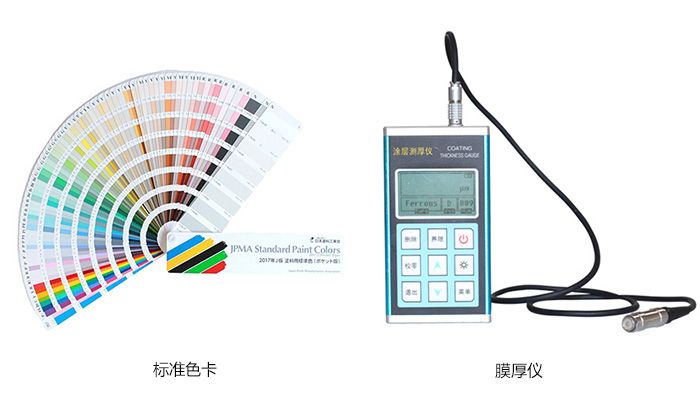

Equipped with all kinds of inspection tools to conduct rigid inspection on the raw material accepting, at the same time to regularly communicate quality data to suppliers and provide training and coaching when necessary, which facilitates improvement on both product quality and quality control capabilities for suppliers.

▲In-process inspection:

Ensure that the key technical information of each production and assembly step is executed and production data related to personnels and key materials is recorded, in order to implement process self-inspection and quality traceback.

Pull test

Terminal pressure connection confirmation

▲Shipping inspection:

100% full product inspection, including: appearance, size, parts installation, wiring, simulation function, security (insulated voltage endurance, grounding)

Insulated voltage endurance test instrument

Ground resistance test instrument

High voltage endurance test instrument

Simulated electrifying test

Screw fastening mark